... or rather, our take on the Garmin GNS430 and GNS530 respectively.

We've had quite a few requests for these units over the years and after making our version of the Aspen EFD1000 we thought that we'd try to apply the same sort of process to these Garmin units.

There are actually three versions of the RNS430 and RNS530, as we've found that each simulator is being made or (more likely) has already been constructed in a certain way and any additional navigation units need to be able to fit around and/or into these constraints.

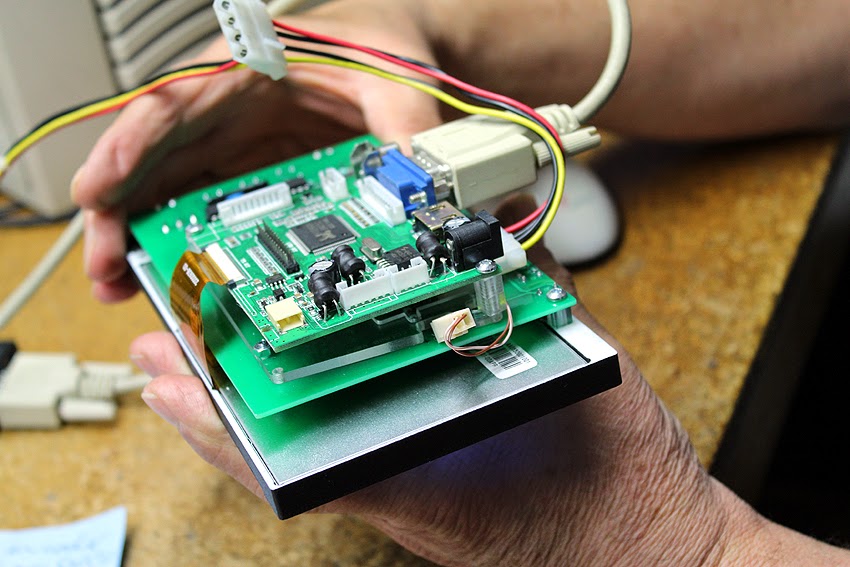

The types are basically (a) the Bezel Only, which can be used in front of an already installed MIP LCD screen, (b) the Bezel Only plus a fitted LCD screen - but with no interface board, or (c) the Bezel with a fitted LCD screen and its integrated interface board.

The versions that we're showing below are the Bezel Only units, as they just happen to be the ones that we got the first orders for; although, paradoxically, they're also the most difficult to make.

The dimensions of our units as compared with the official Garmin panels are below:

Ruscool RNS530: 162mm(w) x 120.4mm(h) / 6.38" x 4.74"

Garmin GNS530: 159mm(w) x 117mm(h) / 6.25" x 4.60"

Ruscool RNS430: 162mm(w) x 83mm(h) / 6.38" x 3.27"

Garmin GNS430: 159mm(w) x 67mm(h) / 6.25" x 2.65"

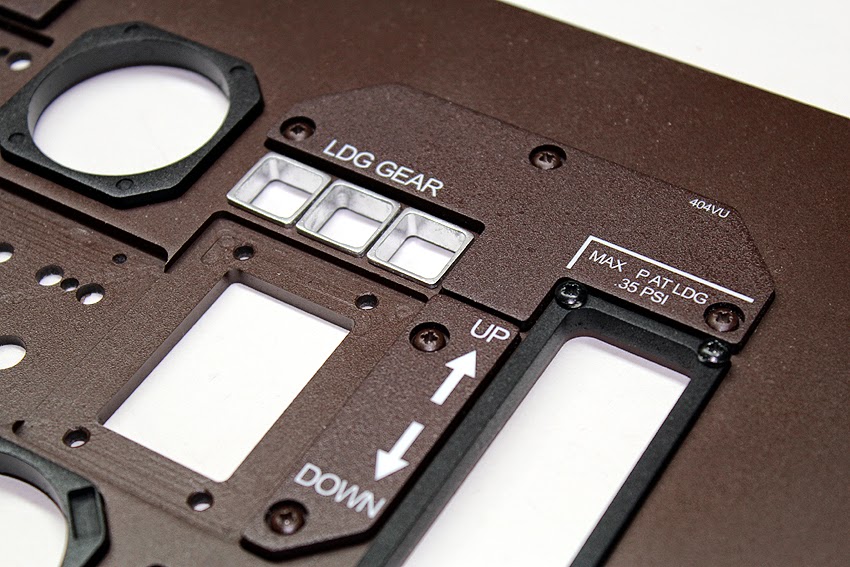

And now, on to the photos ... the RNS430 first

The three screws that you can see here are the means by which

the unit is mounted onto the main instrument panel.

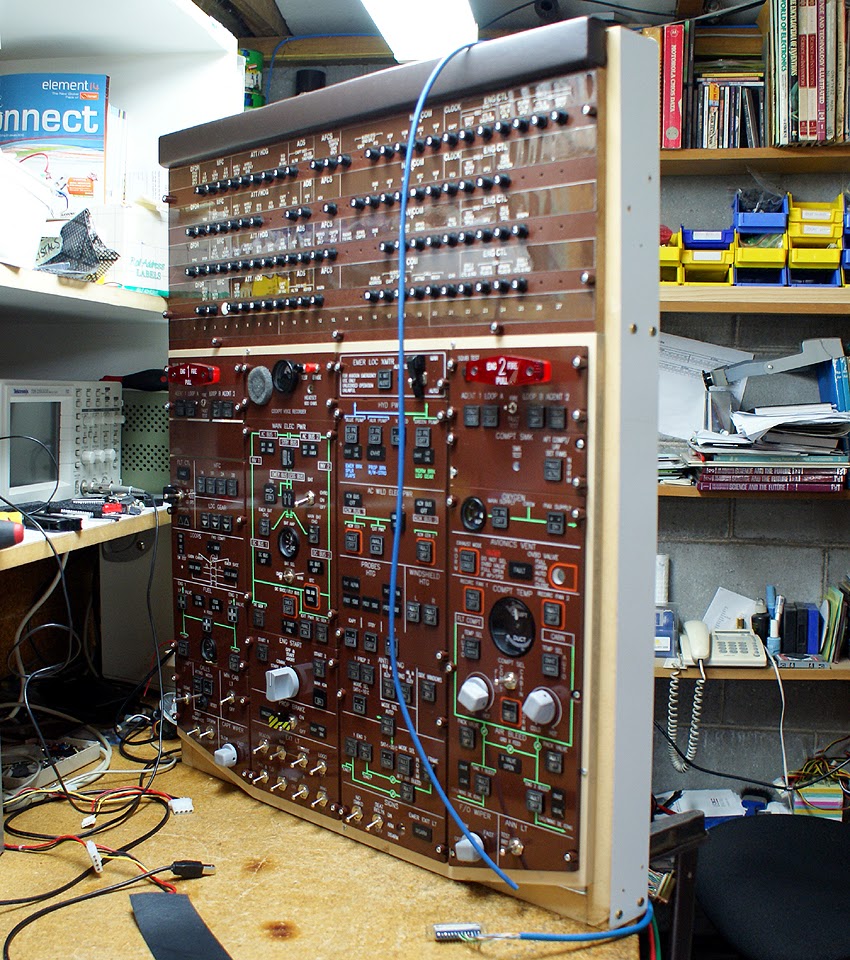

And below, again as the Bezel Only version, is the RNS530

.jpg)

.jpg)