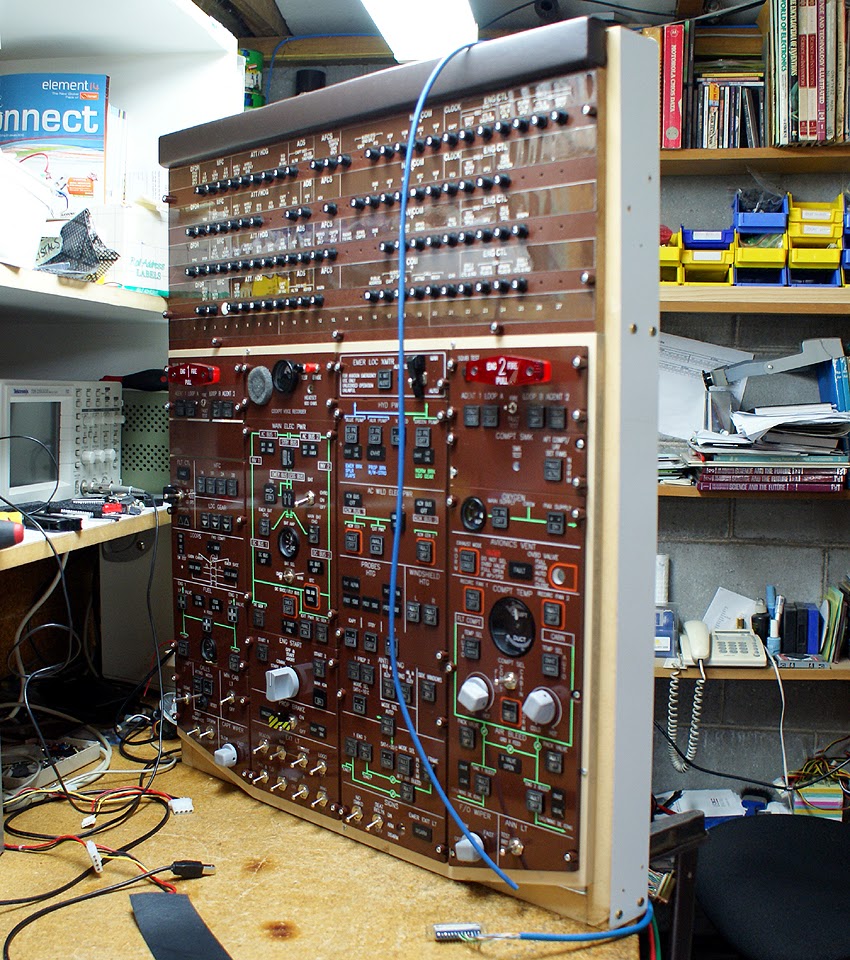

It's been a while since any work has really been done on my own ATR simulator, although over the Christmas holiday break this year (wow, that was a while back now!) I managed to get a few things done. Most of the work was behind-the-scenes sort of stuff, with some programming work being carried out that allows yet more overhead buttons and annunciators to be properly interfaced, although a visible portion of the progress (and the one most obvious to visitors) is the newly made Central MIP, which overlays the PC monitor.

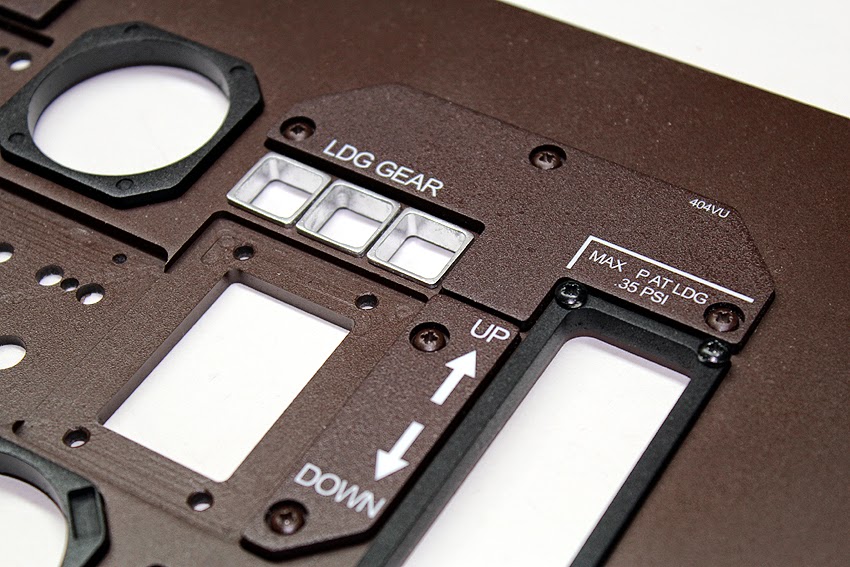

Below are a few quick photos, the first image being the Central MIP prior to painting and the fitting of the gauge bezels and other panels et cetera ...

And below is the original photograph of an actual ATR72 cockpit that I was lucky enough to go and visit a few years back, and which the design of the above panel(s) was based on. There are discrepancies with various measurements here and there due to space constraints and the like, although hopefully the overall essence of the panel has been maintained.

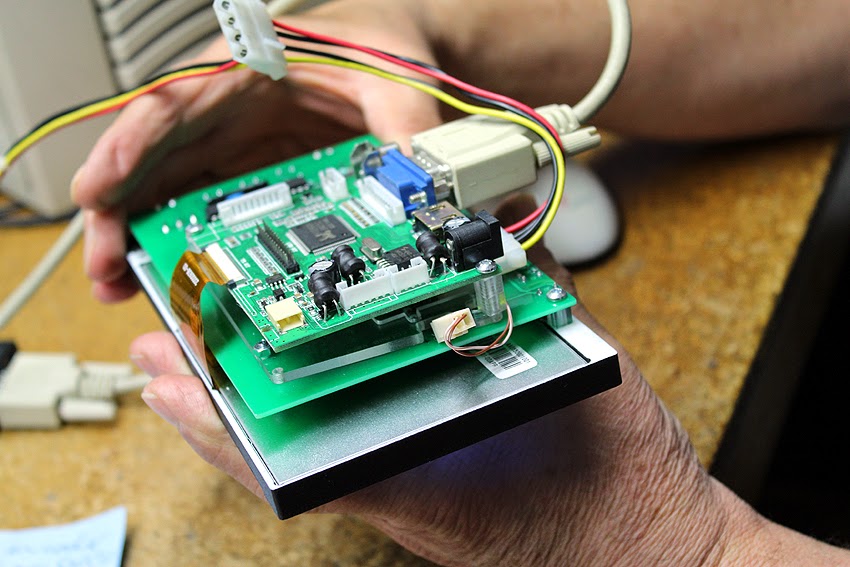

There's not really too much to show with regards to the additional interfacing that was accomplished on the overhead as the majority of it related to implementing some of the new abilities on our Input and Output cards, although I did have the overhead section down from above the simulator for the first time in a long while and so took a coupe of shots of it.

And I'm guessing that'll be about it unless we can find time for some Christmas holidays again this year ... !

.jpg)

.jpg)